Testing

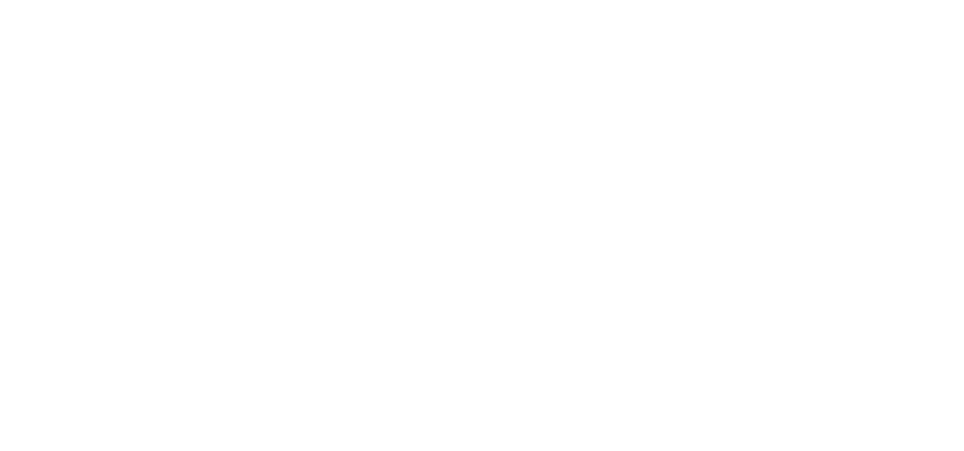

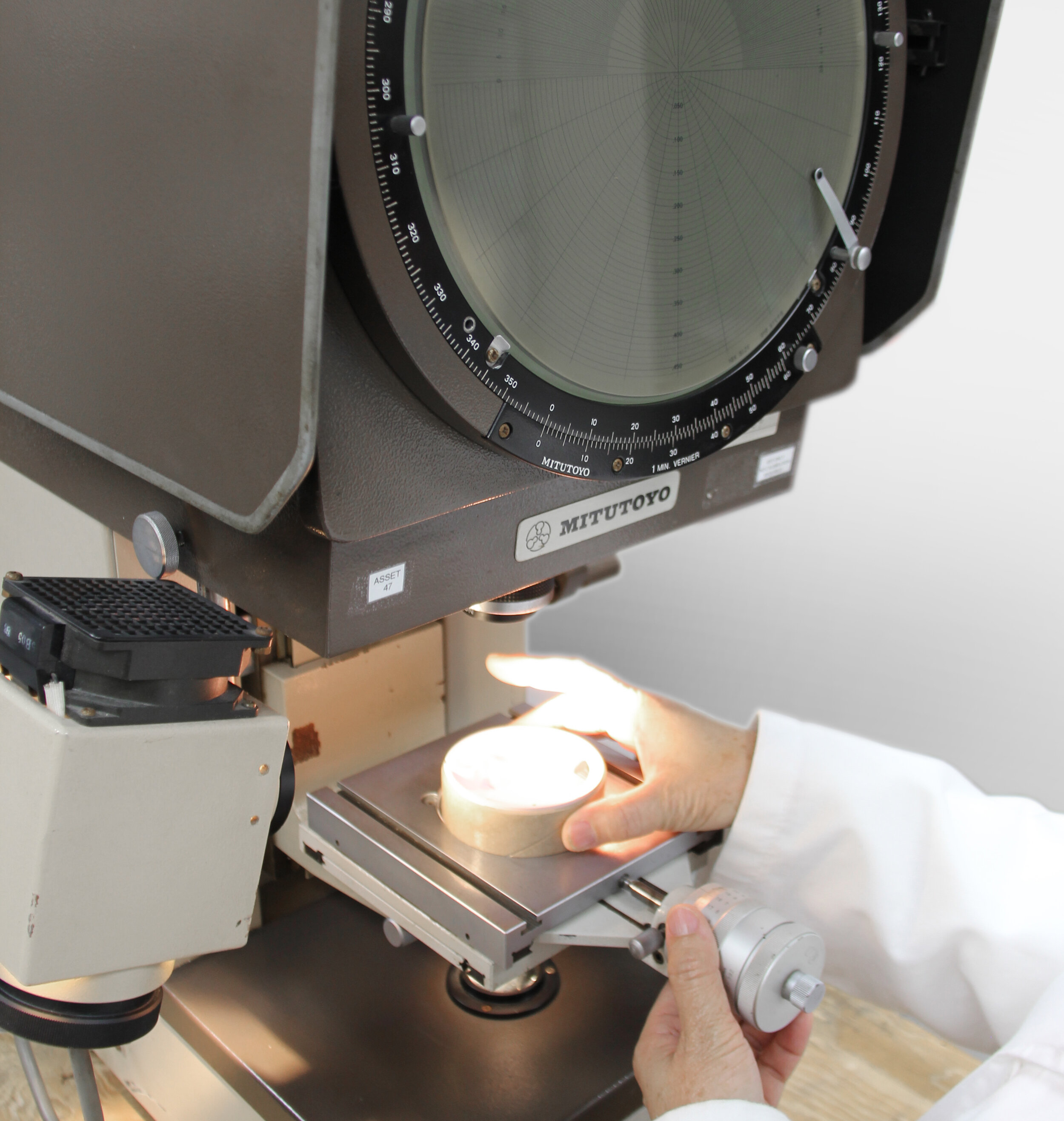

Design Catapult Manufacturing tests simple to complex electro-mechanical devices with various sophisticated equipment based on the specifications for each project. Below is a list of common tests performed.

Dual Channel Oscilloscope Testing - is used to observe varying signal voltages on a two-dimensional plot.

Ground Continuity Tester Analyzer - ensures that power cables are properly grounding electrical outputs.

High Potential Voltage (HIPOT) Test - the Hipot test ensures there is no electrical current flow from one point to another which is the opposite of the continuity test.

Vacuum Testing - ensures there are no pressure leaks in hosing systems.

Digital Volt Meter Testing - to measure the electrical differences between two points in an electrical circuit.

Peel Test – used to determine the amount of strength required to peel laminate from board.

Solder Pot Test – determines the solderability of plated through hole (PTHs).

Solder Float Test – measures the degree of thermal stress that a PCB hole can withstand.

Resistivity of Solvent Extract (ROSE) Testing – highly reliable test used to ensure that your board does not contain significant surface debris remaining from manufacturing processes or excess conductive material.

Automated Optical Inspection AOI – performed to check solder quality and verify pad and trace connections.

Time Domain Reflectometry (TDR) – typically done to measure characteristic impedances. Can determine if differential traces are matched for good signal integrity.

X-ray Inspection – used to view the PCB’s internal construction; including layers and vias. Can also be used to view inside of component packages to verify device types and authenticity.

Design Catapult Manufacturing will accept most additional testing requirements, please contact us for more information.

To find out more about our testing services, please contact us at (949) 522-6789 or if you want to get started now request your free quote.